Energy and Carbon

We've taken a socially responsible approach to our energy efficiency in the past and already have a strong infrastructure of sustainable facilities to build upon.

Scroll to content

Developing infrastructure

The University is planning to develop a solar PV farm comprising of around 39,000 solar panels that will aim to produce all of the University's required energy when combined with our existing resources. Follow the project and have your say by clicking the link.

Solar Farm

Green energy investment

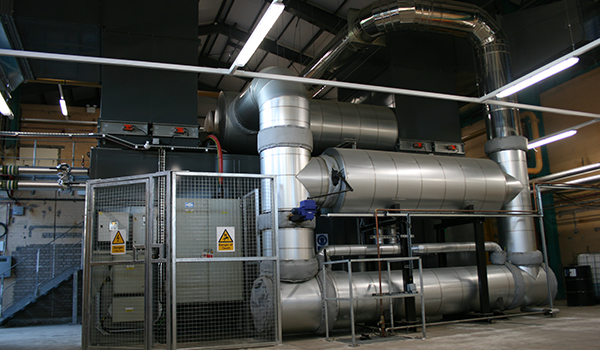

The University is set to virtually eliminate the use of gas for heating on its Bailrigg campus through the creation of a new ‘Low Carbon Energy Centre’ following more than £21 million of funding from the Government’s Green Heat Network Fund (GHNF).

The Centre will use air source heat pumps, thermal storage and electrical infrastructure to create an innovative heat network providing 45 GWh of low carbon heat, which will be sufficient to provide heating and hot water for nearly the entire campus.